Top Guidelines Of Sandblasting And Painting

Table of ContentsExamine This Report about Sandblasting And PaintingWhat Does Sandblasting And Painting Near Me Do?How Sandblasting can Save You Time, Stress, and Money.All About Sandblasting Air CompressorThe 8-Second Trick For Sandblasting

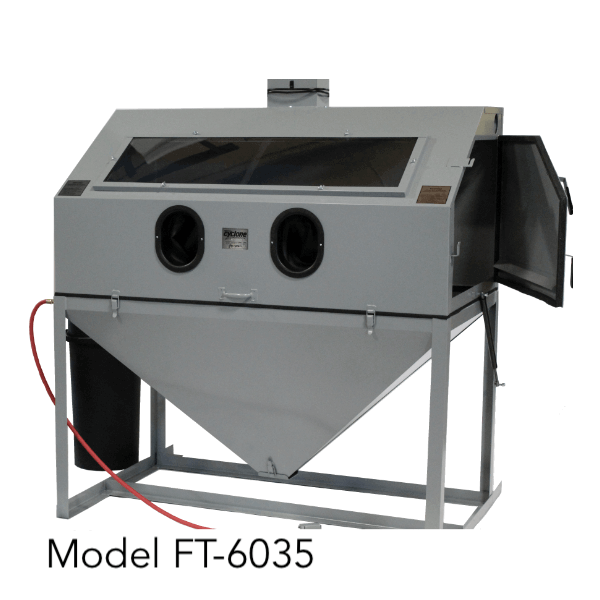

Mobile applications might or might not reuse the rough. A blast cabinet is basically a shut loophole system that enables the operator to blow up the part and recycle the abrasive. It usually is composed of four parts; the control (closet), the unpleasant blowing up system, the unpleasant recycling system and also the dirt collection.Automated blast cabinets are also utilized to process huge amounts of the very same component as well as might include multiple blast nozzles and a part conveyance system. There are 3 systems commonly utilized in a blast closet. 2, siphon and pressure, are completely dry and also one is damp: A siphon blast system (suction blast system) uses the compressed air to develop vacuum in a chamber (called the blast gun).

The abrasive mixture takes a trip with a nozzle that directs the bits towards the surface or work surface. Nozzles are available in a range of shapes, sizes, and products. Tungsten carbide is the lining material usually used for mineral abrasives. Silicon carbide and boron carbide nozzles are extra use resistant and also are often made use of with more challenging abrasives such as aluminium oxide.

Sandblasting And Painting Things To Know Before You Buy

Each application might call for making use of several tools, nevertheless, there are several crucial elements that can be located in a regular blast room: An unit or containment system, normally the room itself, made to remain closed to prevent blast media from getting away A blowing up system; wheel blasting and air blasting systems are frequently utilized A blast pot a pressurized container filled with rough blowing up media A dust collection system which filters the air in the space as well as avoids particle issue from getting away A material recycling or media improvement system to accumulate rough blowing up media so it can be made use of once more; these can be automated mechanical or pneumatically-driven systems mounted in the floor of the blast space, or the blast media can be gathered manually by sweeping or shovelling the product back right into the blast pot Added devices can be added for benefit as well as boosted usability, such as overhead cranes for manoeuvring the workpiece, wall-mounted units with multiple axes that enable the operator to reach all sides of the work surface, as well as sound-dampening products utilized to minimize noise levels.

To counter this risk, silica sand for blasting is typically coated with materials to manage the dust.

Getting The Sandblasting Air Compressor To Work

Silica is a common abrasive in nations where it is not banned. Garnet is extra costly than silica sand, but if made use of appropriately, will certainly supply equal production rates while creating much less dust and no safety and security dangers from ingesting the dirt.

Numerous customers agree to pay additional for jeans that have the look of being made use of. To provide the textiles the right worn look sandblasting is made use of. Sandblasting has the threat of triggering silicosis to the employees, and also in Turkey, more than 5,000 employees in the textile market experience silicosis, as well as 46 individuals are known to have actually died from it.

The Buzz on Sandblasting At Home

's Fair Profession Center carried out a survey among 17 fabric firms that showed really few were aware of the risks caused by manually sandblasting denims. A number of firms stated they would certainly abolish this strategy from their very own manufacturing.

Stucco Kid offers sand blasting or next page poly preparation services as required actions on re-stuccoing your home. The existing condition of your stucco walls are the identifying aspect of what process is best for you. Both processes feature a lifetime service warranty and produce a structurally audio substratum for the leading coat to abide by. sandblasting adalah.

Sandblasting is also called unpleasant blowing up. Basically, it is the procedure of forcibly pushing a stream of rough material versus a surface. The sandblasting operation is done under high pressure to smooth a harsh surface, rough up a smooth/Shape the surface to eliminate its impurities. There are a number of variations of this contact form sandblasting process like grain blasting, Soft drink blasting as well as fired blasting.

Some Of Sandblasting Alternatives

If your task profile belongs to sandblasting or you owned a company that associated with the same procedure, you require to stick with us. In this short article, we will talk about sand blowing up makers products and also its pros and corns. But before it, allow me additionally get rid of several of the information of its operation.

- This procedure is best matched for steel surfaces, to stop moisture build-up as well as prevent water invasion in the surface area. Sandblasting is the process of pushing abrasive by making use of the pressurized liquid or pressed gas as propellant. There are find more information lots of generic terms for this process that is generally connected to the sandblasting rough media used for this procedure.